- Home

- About Us

-

Products

-

Oil-injected screw compressor

- Single stage compression power frequency S series

- Single stage compression power frequency SH series

- Permanent magnet variable frequency single-stage compression ZVC series

- Permanent magnet variable frequency single-stage compression SVC series

- Permanent magnet variable frequency low-voltage SLVC series

- Dual stage compression power frequency S series

- Dual stage compression permanent magnet variable frequency SVC series

- Dual stage compression high-efficiency variable frequency SV series

- Oil cooling integrated single-stage compression SOC series

- Oil cooling integrated two-stage compression SOC series

-

Oil free screw air compressor

- Oil free vortex SWO series

- Water lubricated single-stage compression power frequency series

- Water lubrication single-stage compression frequency conversion series

- Dry oil-free two-stage compression power frequency series

- Dry oil-free two-stage compression frequency conversion series

- Dry oil-free single-stage compression permanent magnet frequency conversion series

- Dry oil-free screw blower

- Gear centrifugal air compressor

- Magnetic levitation centrifugal air compressor

- Post processing equipment

-

Oil-injected screw compressor

- Company Appearance

- News Center

- Service and Support

- Contact Us

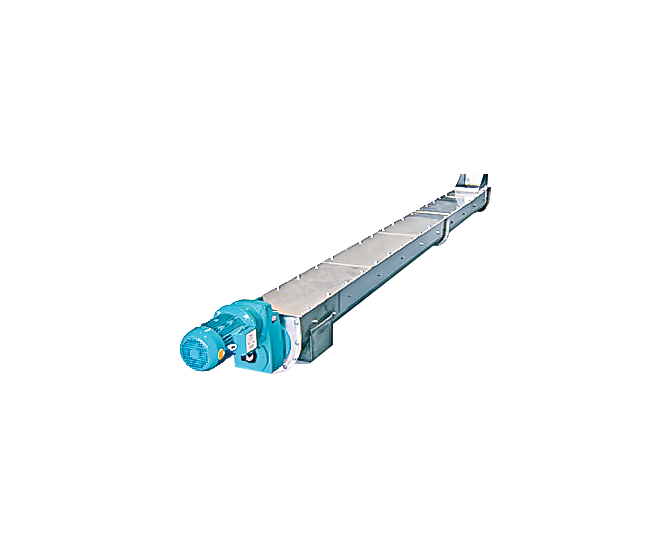

Screw Conveyor

Screw conveyor according to the conveying form is divided into shaft screw conveyor and shaftless screw conveyor. According to the appearance, it is divided into U shape screw conveyor and tube type screw conveyor. Shaft screw conveyor is suitable for the non-sticky powder material and small particle material such as cement, fly ash, lime, food, etc. Shaftless screw conveyor is suitable for conveying sticky and easy-winding materials such as sludge, biomass, litter, fibers, etc.

-

Conveying Distance≤30m

-

Conveying Capacity100m³/h

-

Application Industryuitable for various industries such as building materials, chemical industry, electric power, metallurgy, coal mining and food etc.. (For more, please click “Free Consultation”)

-

Applicable MaterialsApplicable for conveying powder, granules and small lump materials block in horizontal or oblique such as cement, fly ash, pesticides, titanium dioxide, paint, etc..The material temperature is less than 200 ℃. Screw conveyor is not suitable for transportation of perishable, high viscosity, or easy to agglomerate materials.

Product Advantages

-

High efficiency conveying

Adopt new hanging type with bearing frame hanging in the middle to increase the delivery space for materials and also reduce the resistance of logistics. Together with small diameter, high rotation speed, changed screw pitch to ensure smooth, fast and uniform feeding.01

-

rotation speed, changed screw pitch to ensure smooth, fast and uniform feeding.

Casually arrangementhe shell is made of high quality seamless steel tube, each section is connected by the flanges and become a whole piece. No matter it is horizontal one or inclined one, it can deliver materials continuously. It can connected and fixed with the auxiliary device and no need for foundation. Taking fully use of space, can be removed and disassembled easily.02 -

Diversified connection

Inlet and discharging port can use flange connection, , cloth connection, cloth with derrick connection, universal interface connections, and other forms.03

-

Reliable sealing

The joint of casing tube is with the seepage water device, process hole has carefully improved to avoid materials blocked or machine stops due to the cement agglomerate inside the tube resulting in rain infiltration.04

-

No need to add oil

With unique intermediate bearing materials, it can reduce friction and also it is anti-abrasive and can self-lubricate, so it is no need to add lubricate even running for a long period. What’s more, it also avoid the side effect on the shaft sleeve and shaft due to the possible mixture of lube and materials.05

Contact Information

-

unknow

-

86-21-67290898