- Home

- About Us

-

Products

-

Oil-injected screw compressor

- Single stage compression power frequency S series

- Single stage compression power frequency SH series

- Permanent magnet variable frequency single-stage compression ZVC series

- Permanent magnet variable frequency single-stage compression SVC series

- Permanent magnet variable frequency low-voltage SLVC series

- Dual stage compression power frequency S series

- Dual stage compression permanent magnet variable frequency SVC series

- Dual stage compression high-efficiency variable frequency SV series

- Oil cooling integrated single-stage compression SOC series

- Oil cooling integrated two-stage compression SOC series

-

Oil free screw air compressor

- Oil free vortex SWO series

- Water lubricated single-stage compression power frequency series

- Water lubrication single-stage compression frequency conversion series

- Dry oil-free two-stage compression power frequency series

- Dry oil-free two-stage compression frequency conversion series

- Dry oil-free single-stage compression permanent magnet frequency conversion series

- Dry oil-free screw blower

- Gear centrifugal air compressor

- Magnetic levitation centrifugal air compressor

- Post processing equipment

-

Oil-injected screw compressor

- Company Appearance

- News Center

- Service and Support

- Contact Us

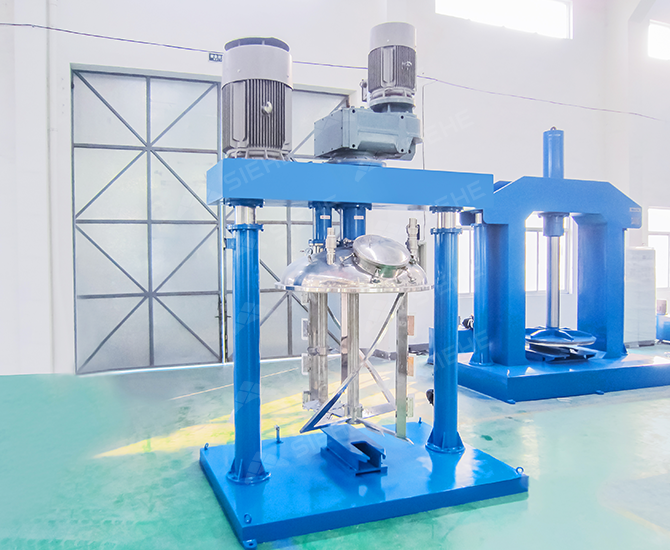

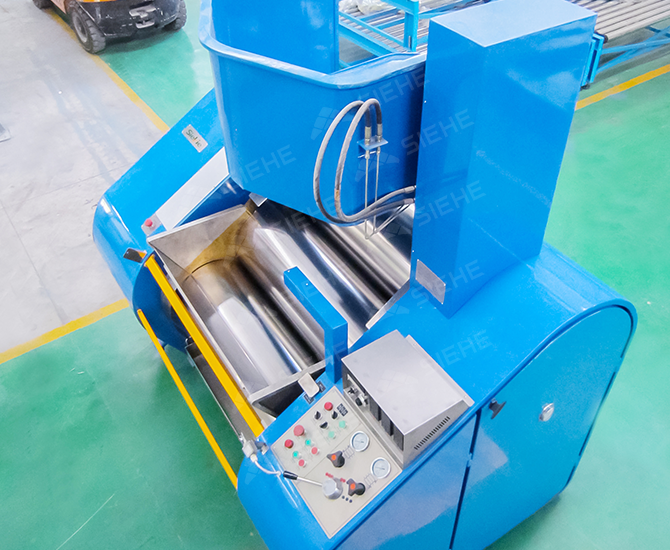

Ink Complete Production Line

SIEHE industry provides design and manufacturing of ink complete production line including: water-based ink, UV ink, inkjet, etc. Ink production line adopts raw materials automatic charging, metering system, dispersing and milling system(basket mill/horizontal beads mill/tri-roller mill), mixing system, cleaning system, automatic control system, automatic filling machine, etc advanced manufacturing method. The Completely automatic production process reduces workloads and avoids quality problems caused by human factors and herein, improves the products quality and efficiency to large extent.

-

MaterialsWater-based ink, solvent-based ink

-

CharacteristicsViscosity ≤200,000 cps

-

Capacity1,000T-10,000T/year

-

ApplicationSuitable for inks, according to solvent: water-based ink, UV ink; according to plate type: offset print, relief block,lithographic plate, screen printing, inkjet, etc. (More information please click FREE CONSULTATION)

Product Advantages

-

Good fineness and High Stability

Basket mill, horizontal beads mill, emulsifier, tri-roller mill, etc high fineness milling machine are applied in production lines according to production process and products characteristics(materials viscosity) to mill and thin raw materials. Ground materials show good products with good fineness, high stability, small chromatism and less pollution.01 -

Environmentally-friendly and Easy Operation

The entire complete plant including storage of raw materials, metering, addition, medium products and finial products transmission and filling are closed and automatic, which is environmental-friendly and easy to operate.02

-

Various of Products

SIEHE industry have rich experience in design ink manufacturing equipment in high, middle and low viscosity according to customers requirements.03

-

Highly Automatic

Powder and liquid storage and batching system, automatic filling system, PLC control system are optional according to process to realize the automatic produce and remote control.04

Contact Information

-

unknow

-

86-21-67290898