- Home

- About Us

-

Products

-

Oil-injected screw compressor

- Single stage compression power frequency S series

- Single stage compression power frequency SH series

- Permanent magnet variable frequency single-stage compression ZVC series

- Permanent magnet variable frequency single-stage compression SVC series

- Permanent magnet variable frequency low-voltage SLVC series

- Dual stage compression power frequency S series

- Dual stage compression permanent magnet variable frequency SVC series

- Dual stage compression high-efficiency variable frequency SV series

- Oil cooling integrated single-stage compression SOC series

- Oil cooling integrated two-stage compression SOC series

-

Oil free screw air compressor

- Oil free vortex SWO series

- Water lubricated single-stage compression power frequency series

- Water lubrication single-stage compression frequency conversion series

- Dry oil-free two-stage compression power frequency series

- Dry oil-free two-stage compression frequency conversion series

- Dry oil-free single-stage compression permanent magnet frequency conversion series

- Dry oil-free screw blower

- Gear centrifugal air compressor

- Magnetic levitation centrifugal air compressor

- Post processing equipment

-

Oil-injected screw compressor

- Company Appearance

- News Center

- Service and Support

- Contact Us

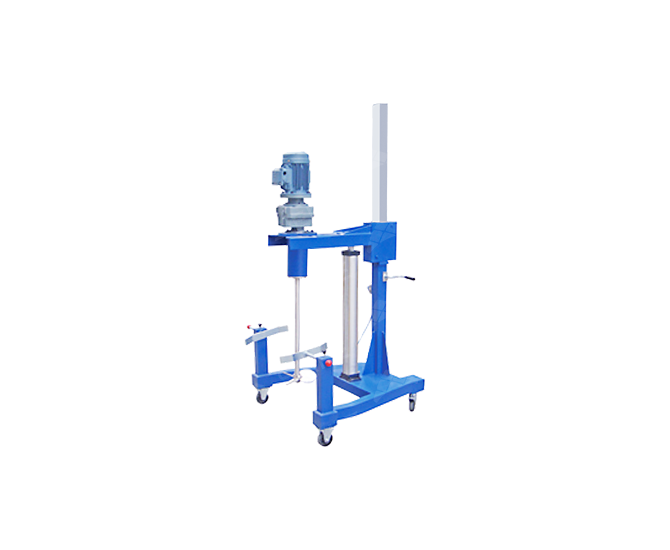

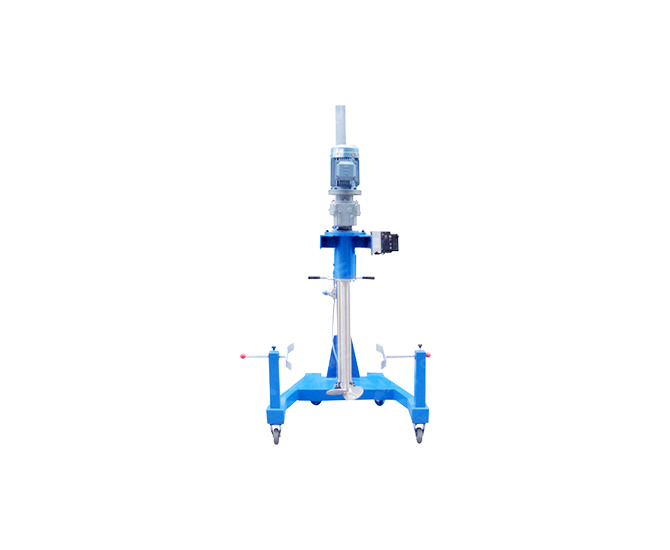

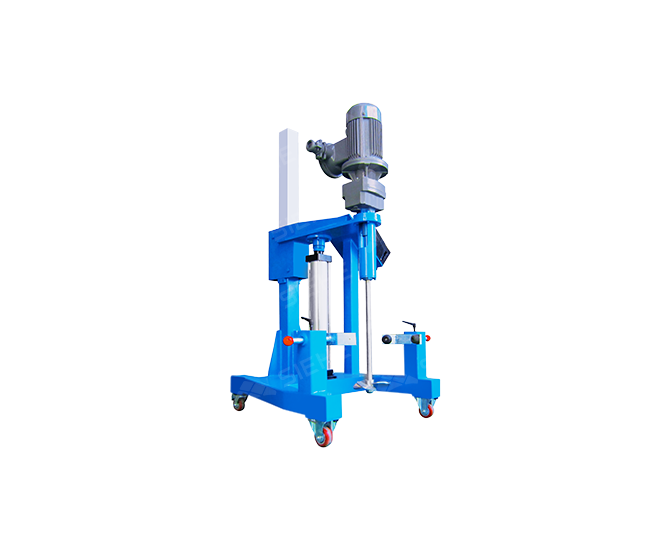

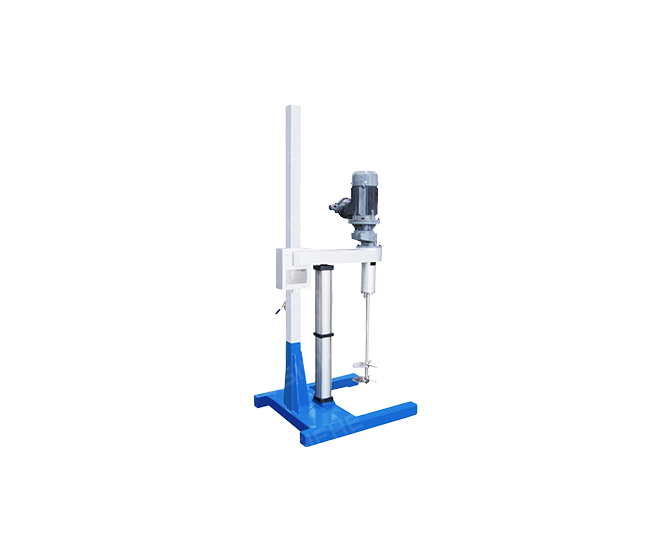

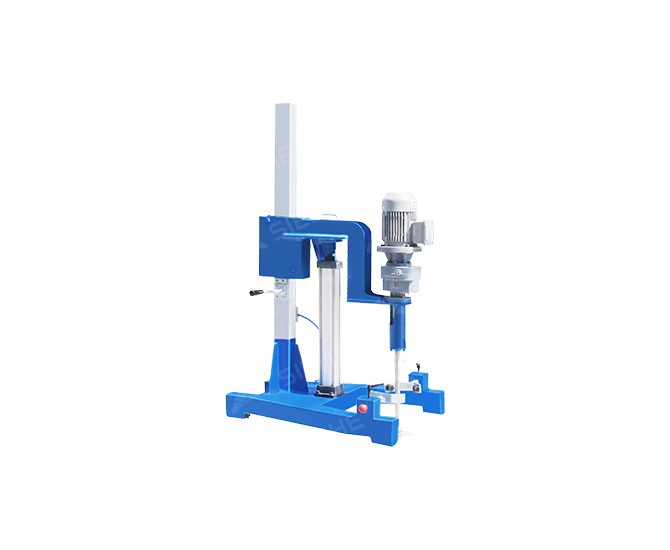

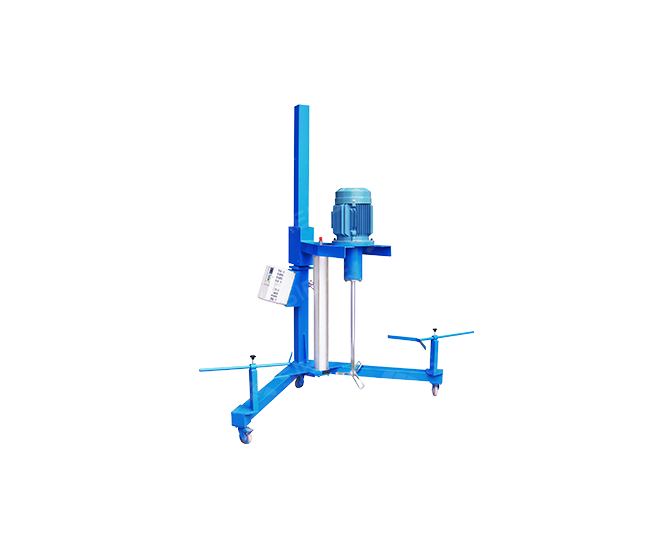

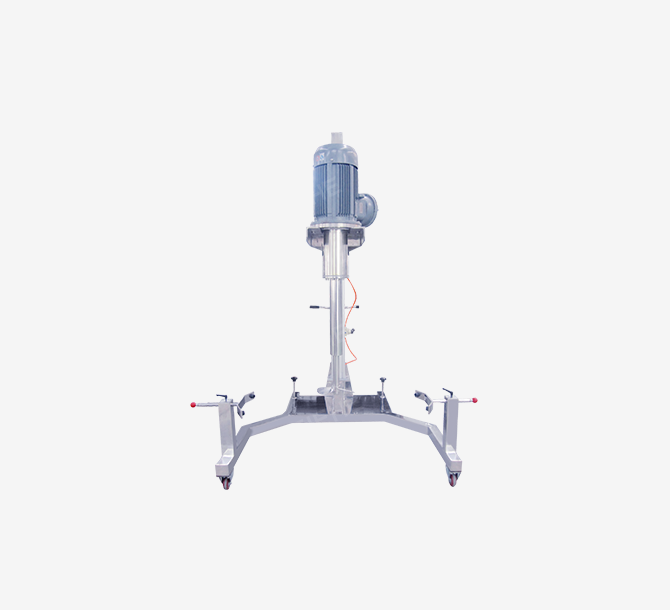

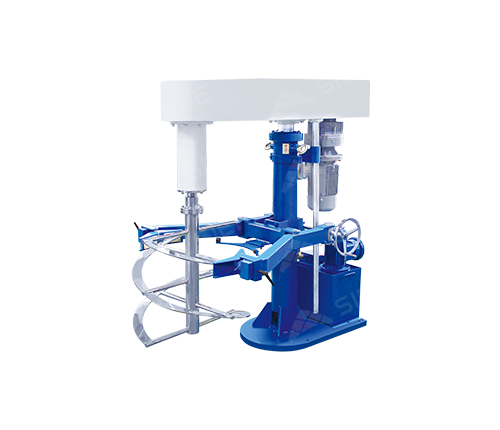

Mixer (Pneumatic Lifting)

Pneumatic Lifting Mixer has the feature of simple lifting, good mixing effect, beautiful structure, beneficial price, and high performance. It is used for small batch production of factories, scientific research institutions and colleges. The equipment is equipment with inverter various speed control, can be used continuously for a long period of time, stable operation and low noise; Various optional mixing paddle, easy disassemble and change; The lifting structure use cylinder as actuator, environmental protection and no pollution, it is an ideal equipment for small batch production.

-

Viscosidade do material≤50,000 cps

-

Capacidade de Produção50-1000L

-

Application IndustrySuitable for stirring and mixing materials in industries such as biology, pharmacy, food, coating, ink, adhesive, dyestuff, pesticide, etc.. (For more application industry, please click “Free Consultation” )

-

Applicable MaterialsMaterials shall be with viscosity less than 50,000cps, various slurry with solid content under 60% such as emulsion paint, industrial paint, water-based ink, pesticide, adhesive etc..

Product Advantages

-

High mixing efficiency, excellent product quality

SIEHE Group has years of application experience is various industries. Reasonable agitator and rotation speed will be recommended as per the materials property and different mixing effect requirements. And the materials will carry out axial and radial motion at same time to mix the materials thoroughly and uniformly within a short period.01

-

Safe and convenient operation

The equipment equipped with lock and lifting handle for quick lifting and fixed; Electric control system and equipment of one-pieced design; With tank clamping device.02

-

Easy move

Occupied little space, with castor and foot brake device, easy to move or fix.03

-

Customized options

Different options are available such as explosion-proof type, closed type, etc.. Material can be customized to be SS321 \SS316L,with tank of different specification.04

Working Principle

Mixing agitator driven by the power unit rotates in a fixed direction, which drive the materials to rotate in axial and radial direction; And the materials inside the tank, at the same time, also do axial and circular motion. So materials can be dispersed and mixed properly with high efficiency.

Pneumatic lifting mixer drives cylinder working by point rotation of pneumatic valve and electromagnetic valve to achieve the motor and working head up and down.

Working Principle

Technical Parameter

| Model | Motor Power(kw) | Speed

① |

Mixing Paddle Dia(mm)

② |

Material

③ |

Capacity (L) ④ |

Lift (mm) ⑤ |

Weight(kg) ⑥ |

|---|---|---|---|---|---|---|---|

| SJBQ-1.1 | 1.1 | 100rpm | 300 | Material contacting part is SS304 Stainless Steel | ≤200 | 600 | 250 |

| SJBQ-1.5 | 1.5 | 85rpm | 350 | Material contacting part is SS304 Stainless Steel | ≤300 | 600 | 250 |

| SJBQ-2.2 | 2.2 | 76rpm | 400 | Material contacting part is SS304 Stainless Steel | ≤500 | 600 | 300 |

| SJBQ-3.0 | 3.0 | 67rpm | 450 | Material contacting part is SS304 Stainless Steel | ≤800 | 800 | 350 |

| SJBQ-4.0 | 4.0 | 60rpm | 500 | Material contacting part is SS304 Stainless Steel | ≤1000 | 800 | 450 |

* ①②④ , State, viscosity, mixing effect shall be specify to confirm the reasonable impeller choice. Batch capacity shall be calculated based on the production requirements. And then

confirm the impeller diameter, speed and height adjustment.

* ③ is chosen based on the materials property such as its corrosiveness etc.

* ④ is date tested based on the materials viscosity 2000cps; The model selection shall be based on the data such as the materials viscosity, specific gravity etc.

* ⑤ shall be based on the size of the tank;

* ⑥Equipment weight associated with reducer, size of tank, and power; is related to the tank size, power, reducer etc.

* The table cannot include all products, please contact with our sales engineers for more information.

Application Industry

Contact Information

-

+86 21 52913185

+86 21 52913186 -

+86 21 52912822